Machinery | Confectionary machinery

Multi-Line PN cooling

Awema Multi Line with Paternoster (PN) features the following highlights:

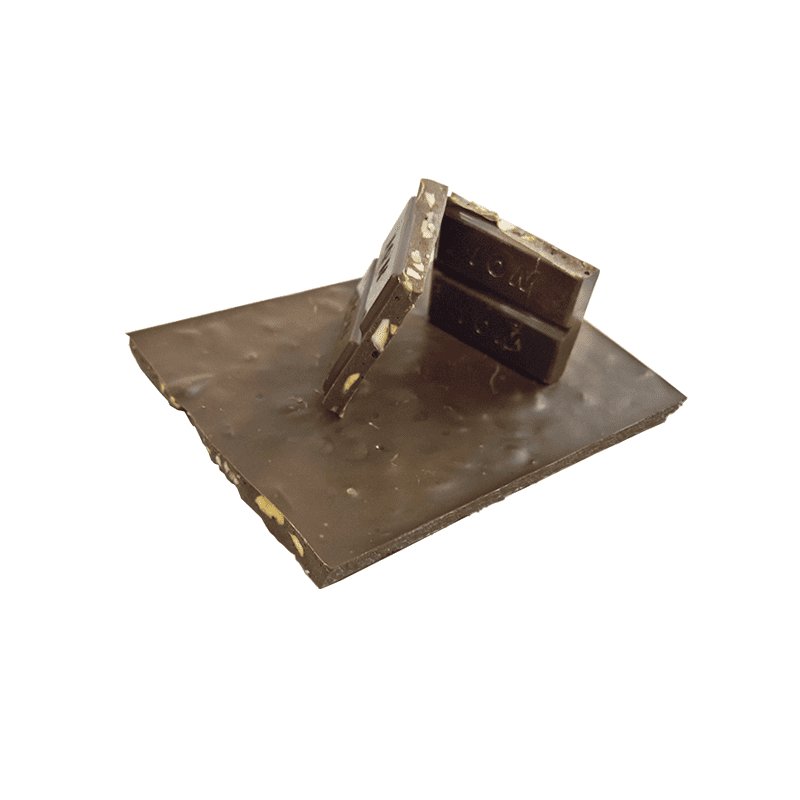

- AWEMA’s State of the art depositing technology for Pralines, Bars and Tablets. In addition products like filled balls, eggs etc. can also be produced with up to 80 % filling and 20 % shell in just one operation.

- Industry leading Oneshot technology for both filled products and precision depositing of solid chocolate

- Layout for ultra-compact footprint of the Line

- Very efficient tower cooling (Paternoster-System)

- Entire line is controlled on the UDM including recipe call-off and fully automatic control of the production process,

- Best in class energy consumption

- Low maintenance costs

- Several Line Capacities available depending on the depositor model and cooling time

- Free Remote Control for customer assistance included

- Further Options: Inclusion mixer, full nut depositor, decorating devices, bookmould handling devices

Awema Multi Lines are made to fit:

We offer our Multi Line either as a modular solution (Eco Line) or as fully tailored line integration our best-in-class deposting machines with proven components:

- Eco Line is a cost-efficient, modular solution using a tower cooling system

- Multi Line tailored to your exact requirements based on proved, leading-edge technology

Please contact our sales specialists.

Request infos Download PDF Watch Video

About Lines

Awema Multi Lines are fully customized:

- Output range from 200 kg/h up to 3’000 kg/h

- 3 to 24 moulds / minute

- Up to 8 decorating robots

- Integration of optional equipment, e.g. robot based feeding of spinning machines